为什么众多客户选择了我们?

云方是一家通过 ISO 9001:2015 认证的公司,专注于质量。ISO 认证使我们能够在满足与产品相关的法律法规要求的同时满足客户的需求。我们的 ISO 9001:2015 质量管理体系帮助我们识别、衡量、控制和改进各种核心业务流程,最终提高客户满意度。

技术实力

规格齐全

质量保证

工艺先进

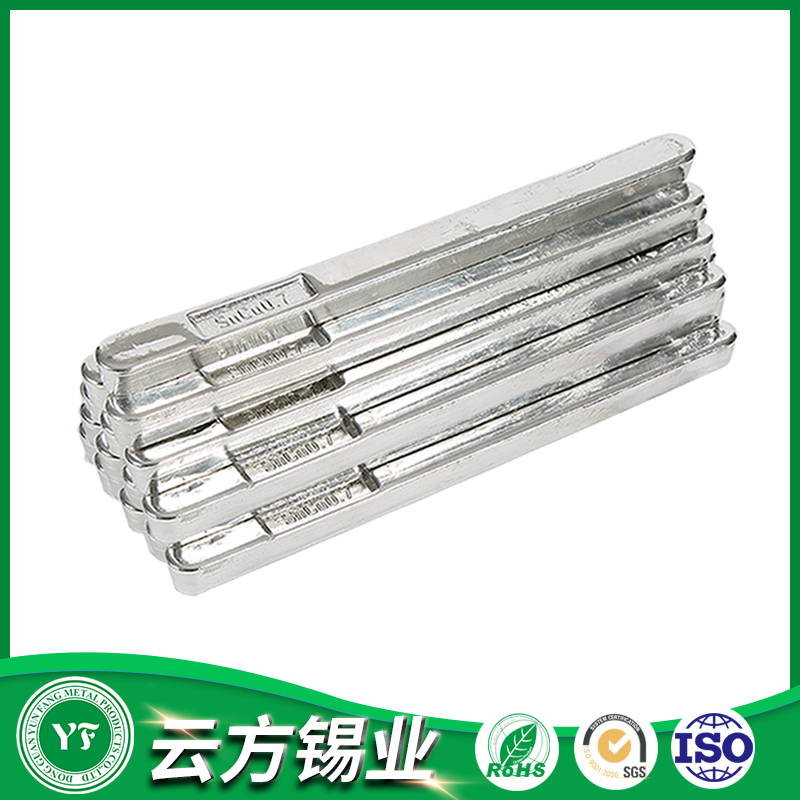

品牌力作

致力于提供全球焊接领域解决方案,为您的焊接需求始终提供,高品质的产品和服务

云方技术研究中心

云方的成功源于我们理解客户需要的不仅仅是优质产品。他们在每一步都需要服务和支持。我们了解全球最新的应用和趋势。从故障排除过程到定制设计的产品和现场培训服务,我们的客户可以从可支配的宝贵服务和技术资源中受益。

云方动态

我们专注于有色金属,例如锡、铅和铋基合金以及银、巴氏合金、铜、锑和辅助助焊剂材料。 我们提供种类繁多的助焊剂化学品和先进的焊接材料,以协助行业广泛的任何应用。 请单击以了解有关云方以及行业内相关资讯的更多信息

在焊锡工艺中锡膏、锡线和锡条该如何选择

我们知道,在焊锡工艺中,锡膏、锡线和锡

SMT贴片加工的锡膏印刷工艺介绍

为了规范SMT车间锡膏印刷工艺,保证锡

Aliquam luctus sem massa

Lorem ipsum dolor si

云方是谁?

云方公司成立于2003年,经过十余年的发展,已成为行业知名的电子材料研发与制造的集团性公司。总部位于东莞,年营收超5亿元,现有员工260多人,业务遍及80多个国家和地区,云方在中国深圳、东莞拥有两大生产基地,在海外印度设有制造基地与研发中心。